It is fair to regard the ‘Welt’ as a seminal revolution in footwear. English shoes before its invention were of simple character; soft and flexible unlined turnshoes. They were comfortable enough for medieval life, but not built for the realities of cobblestone streets, weather, or wear. As cities grew and travel expanded, so too did the necessity for something sturdier.

The Hand Welt

Turnshoes remained the longstanding fashion in England, that is until somewhere amidst the workshops of 16th century Europe, craftsmen hit upon a useful expedient – the sewing together of a narrow strip of leather between the shoe’s upper and its sole in order to attach them. This strip, soon to be known as the welt, allowed the sole to be stitched on separately as well as be easily replaced when it wore out.

By the 18th Century, the hand-welted shoe had become a marker of serious craftsmanship. Every stitch attaching the welt was patiently constructed entirely by hand, using waxed linen thread and a shoemaker’s awl. Whilst hand-welting a single pair often takes days to complete, the process results in footwear that is exceptionally durable and flexible and shaped to the foot.

What is the Hand-Welting Process?

-

Building the Foundation

The shoemaker prepares the insole – the base beneath the foot – and carefully cuts a small lip around its edge. This lip serves as the anchor where the upper (the main body of the shoe) and the welt (a narrow strip of leather) will be joined. -

Stitching by Hand

The upper, lining, and welt are sewn together by hand using thread coated in wax and an awl. As each stitch is drawn tight, a small hollow channel forms beneath the footbed which will next be filled with cork. -

Filling and Finishing

The cavity beneath the insole is filled with cork, which softens and moulds to the foot for comfort over time. -

The Outsole Stitch

Finally, the outsole is stitched to the welt with a second seam. Since the insole and upper are never pierced, the shoe can be resoled in perpetuity without compromising its integrity or comfort.

Hand-welted shoes have been prized since their impetus not only for their longevity but for the understated comfort that came with a leather insole that supported and secured the foot. This fine handiwork succeeded amongst military officers, riders, and the well-dressed and the welted shoe solidified a reputation synonymous with ideas of refinement and quality that remains today.

The Good-year Welt

In the early part of the 19th Century, as industry underwent significant expansion owing to the opening of export trade, American inventor Charles Goodyear Jr was at work on one of the greatest commercial gifts to mankind. He devised a machine that could replicate the meticulous welting process instantaneously with mechanical precision, with a technique now referred to as the “Goodyear Welt”. Towards the turn of the Century, this method spread rapidly, replacing hand welting in more and more places.

What is the Good-year welt process?

-

The Insole and Rib

The insole is fitted with a raised rib that is stitched or glued along its edge, traditionally made from leather or canvas. The rib serves as the foundation for the welt to be attached.

-

The Welt Stitch

Using a Goodyear welting machine, the upper, lining, and welt are stitched to the insole rib in the first seam, known as the welt stitch, forming a secure connection while leaving a narrow cavity beneath.

-

The Cork Filling

Into this cavity, a layer of cork is carefully packed. This natural material provides cushioning, insulation, and gradually conforms to the wearer’s foot, offering a personalised comfort over time.

-

The Outsole Stitch

Finally, the outsole is sewn to the welt in a second seam. Since the upper isn’t pierced during this process, a Goodyear-welted shoe can be resoled 5–10 times without compromising fit or structure.

The strides brought about by Charles Goodyear were met with deep disdain from the contemporary shoemakers of the 19th Century, protests and boycotts took place against factory manufacturers, inflammatory pamphlets were targeted against the Goodyear automation. It certainly had its derisive origins, but both Goodyear and Hand-welted constructions have become integral to the modern fine shoemaking industry, each are valued for their own strengths.

Choosing between a Goodyear welt and a Hand welt ultimately depends on what you value most in your footwear.

Strengths of the Goodyear Construction

Goodyear welted shoes are renowned for their reliability and durability, making them ideal for everyday wear. The welt is stitched strongly and evenly by precise machines, producing a strong, uniform construction that can be resoled multiple times. It is a method that upholds the quality of traditional cordwaining craftsmanship whilst introducing efficiency, allowing for high-quality construction that remains remarkably cost-effective.

For example, Bridlen shoes feature a 360° Goodyear welt with a hand attached leather insole rib – a construction technique rarely offered at this level. This approach combines the efficiency of Goodyear machinery with the density and flexibility offered by handcraft.

The Enduring Power of the Hand-Welt

The hand-welted process represents the most time-honoured form of shoemaking. It is the method which most extends our commiseration to our fellow craftsmen who have exerted their will to the benefit of our experience. Being that one skilled worker has consciously imparted their expertise into its creation, finer elements can be adapted to, such as the adjustment of tension and stitch depth in response to the nuances of both leather and last. With this heightened control, a more balanced and long-lasting build materialises. Further, since the welt is stitched entirely by hand directly into a carved leather rib on the insole, this direct leather-to-leather join creates a construction that is both more pliant and more durable than machine welting. The absence of synthetic or glued components also allows the sole to flex naturally, moulding to the foot with wear, while the dense hand-stitching forms a bond of remarkable longevity and stability.

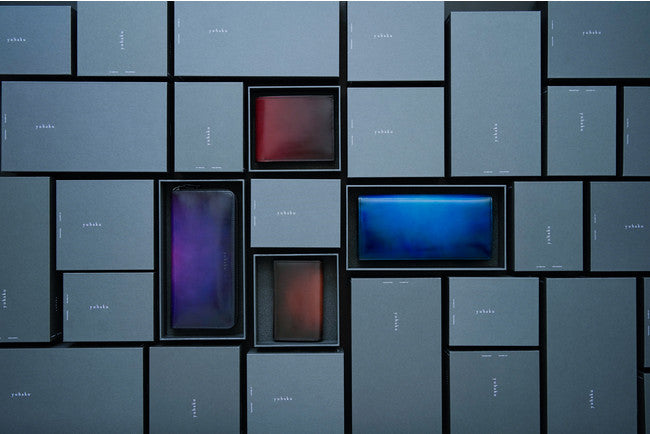

Yearn Shoemakers are one of the few brands in the world that offer exclusively hand-welted shoes in a Ready-to-Wear line; this additional step to their production reflects a genuine dedication to the refinement of traditional artisanship. In addition, each pair features a hand-stitched outsole at the above average density of 8 stitches per inch, with their artisanal line offering 12 stitches per inch.

Between their slight differences, both Hand and Goodyear-welted shoes are great options that uphold the same ideals of being strong, repairable constructions that provide longevity and comfort, ensuring that the artisanal legacy of shoemaking continues with each pair.