Welting is the process by which a strip of leahter (usually) is attached to the perimeter of the outsole of a shoe. It is a crucial part of the construction of a shoe, and there are various methods.

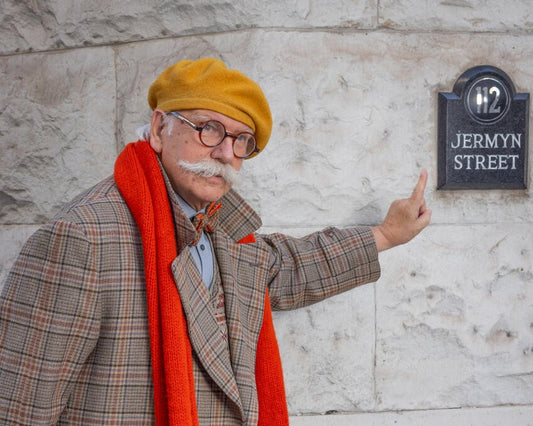

Hand-welting, in comparison to Goodyear machine welting or, God-forbid, cement welting, is a labour-intensive process that results in a more comfortable and flexible shoe. This is for various reasons. For one, the cavity between the insole and midsole is kept to a minimum, so that there need not be thick amount of cork as a filler. A hand-welting process generally allows for a greater amount of leather in the insole, which can better conform to the wearer’s foot over time. The shoe is left on the last for over three whole days, and it takes over half a day to hand-welt each shoe.

Goodyear welting takes its name from Charles Goodyear Jr., whose father started the infamous rubber tyre company. Goodyear Jr. invented a machine that could handwelt the outsole much more quickly than an artisan can by hand. The economic savings can be immense, and goodyear welting is the norm in middle-end shoes. Cement-wenting is the norm in low-end shoes. However, it is hand-welting that is canonical of a high end shoe.

| Cement Welting | Low-end shoes (e.g. Florsheim, most Clarks, Cole Haan) |

| Goodyear Welting |

Middle-end Shoes (e.g. Church's', Loake, Crockett and Jones, John Lobb (Paris), Tricker's) |

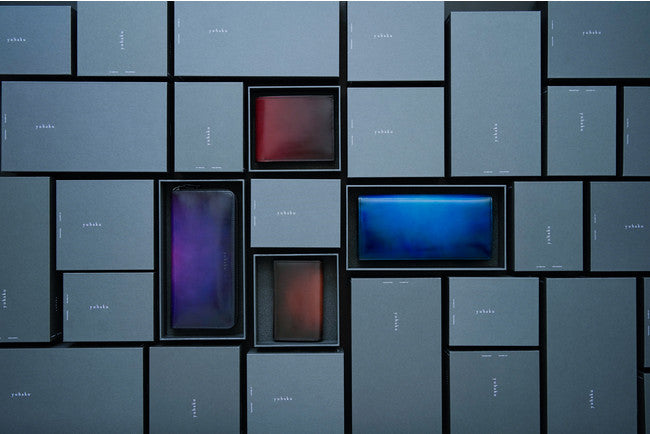

| Hand-welting | High-end Shoes (e.g. Yearn Shoemaker, Crockett and Jones Handgrade, John Lobb (London), Edward Green, Yohei Fukuda) |

Table 1. Cement Welting vs Goodyear welting vs Hand-welting Standard of Shoes

This video depicts a the hand-welting process at the Yearn Shoemaker workshop.